A trusted advisor, providing trusted solutions

With our experience in robots, IoT and similar technologies, we provide solutions to transform manufacturing.

The manufacturing industry often refers to terms such as Industry 4.0, smart factories, factory automation, digital transformation and so forth.

We can help make sense of these to deliver solutions that add business value.

UM Kaizen

A solution to integrate manufacturing data from multiple sources for analytics, process improvement and manufacturing optimization.

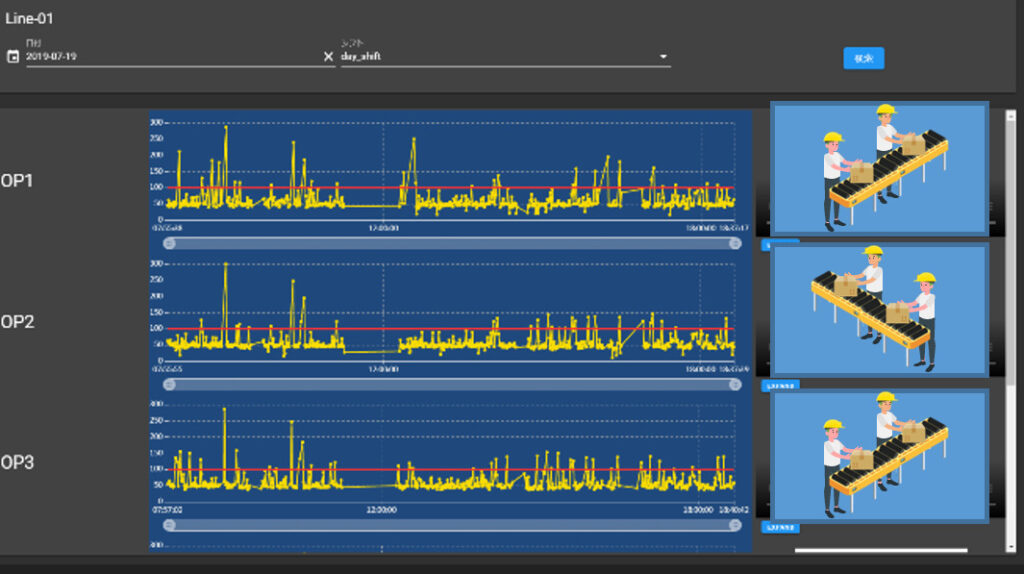

Monitor production staff

Identify variations in the work time of each process, review video footage and analyse against benchmark cycle times.

Interactive, dashboard displays of production metrics facilitate a methodical approach to identify the cause of variations in production.

analySe cycle times to help with the load balancing of cycle times

The variation in working time in each process can be reduced, and waste of work in process can be reduced.

Identify the production ‘pinch points’ where the introduction of automation could have the maximum effect.

If the introduction of equipment / robots is under consideration, UM Kaizen is the tool to help with selection.

Perform error analysis. and conduct ongoing monitoring to ensure the maximum ROI of the investment in tooling.

Integrate with multiple sensors and major PLCs such as Mitsubishi Electric, KEYENCE, and OMRON, and connect to

existing equipment to use UM Kaizen.

Cycle Time Analysis

The variation of cycle time is displayed for each process.

Our global alliance with DENSO WAVE

Our relationship wth DENSO WAVE stretches further than Japan, with projects throughout South East Asia and beyond. Using products such as IoT Data Server to integrate hardware devices to manufacturing software, we have helped customers increase quality and gain manufacturing efficiencies.